INFRASTRUCTURE

We at Cotton Blossom, pride ourselves in having the latest and the best infrastructure that helps meet our clientʼs requirements. This vertically integrated system ensures we exceed the requirements of our business partners.

SPINNING

High quality production begins with the selection of the finest raw materials and the state-of-the-art production facilities with the latest machineries. We spin Organic Grade A & BCI Cotton grown by farmers in Gujarat, Andhra and Maharashtra in a sustainable way, which combines traditional innovation and modern scientific practices. These high quality cotton fibres are processed with the latest machineries from Japan and India to produce yarns and fabrics of the highest quality standards.

We have an installed capacity of 20,000 spindles delivering eleven tons of yarn a day which is certified by the Control Union Certifications for Organic OCS 100 and GOTS.

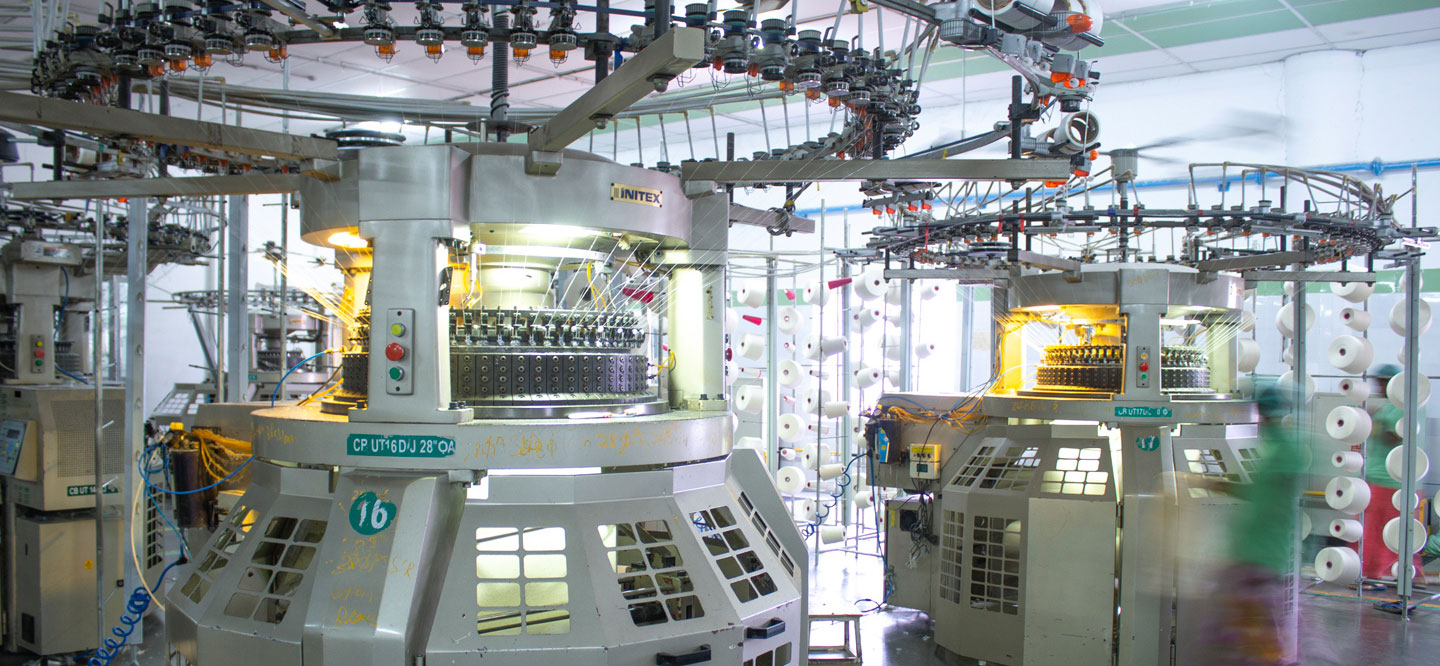

KNITTING

Our Knitting division is equipped with machinery from Unitex Singapore. World renowned for their high precision circular knitting machines. With a current production capacity of 12,000 Kgs of fabric per day and is certified by the Control Union Certifications for Organic OCS 100 and GOTS..

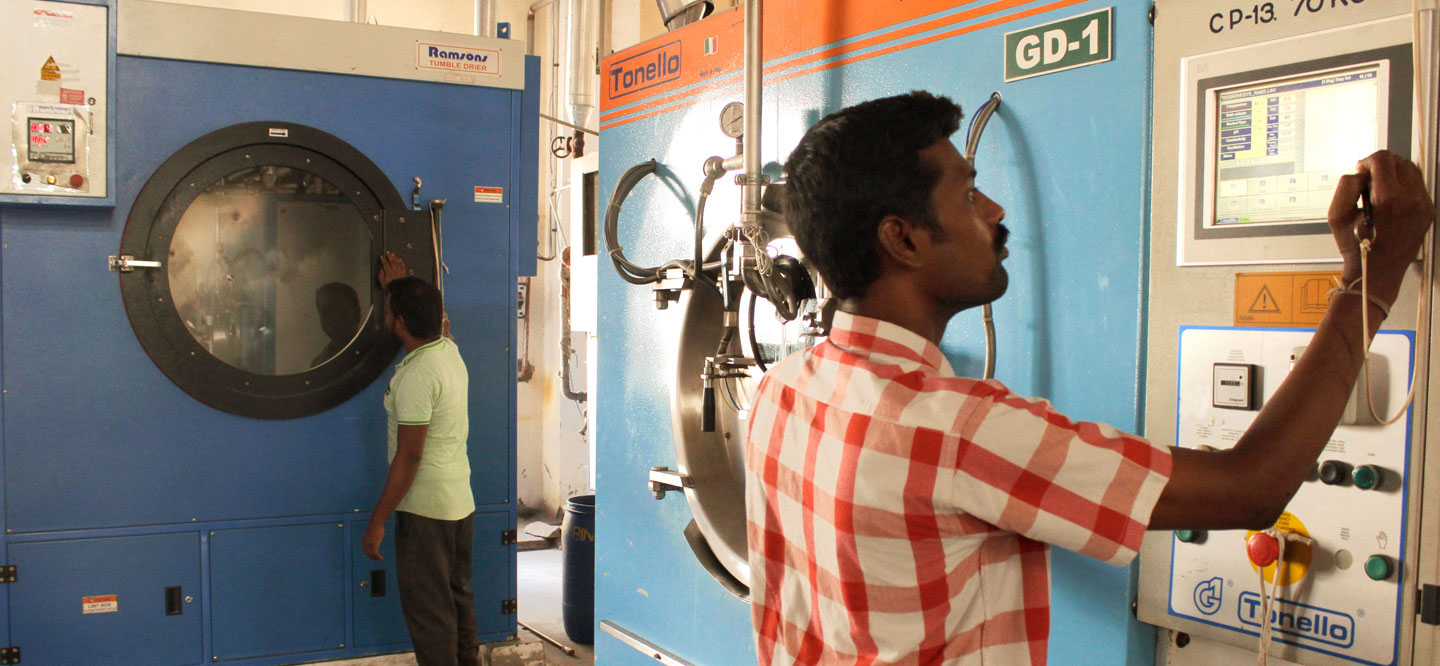

DYEING

Our Dyeing facility uses the latest Low Liquor Air Flow machinery manufactured by THEN, Germany with an automated chemical dosing system that discharges very low effluent and demands minimal human interference during the process. We have an installed capacity of 10,000 kgs of fabric per day. The water treatment plant situated at our facility is complete with chemical, biological, oxidization a four stage reverse osmosis and evaporator features, enables us to function as a Zero Discharge and a C2C Gold Facility™.

EMBROIDERY

Our automated embroidery machines are made in Tajima, Japan equipped with different aspects of Embroidery such as cording, roping, sequins, boring and mirror work that significantly enhances and embellishes the garments. In addition, Applique Laser Cutting Machine and SEIT Laser Bridge enables multitasking of applique and embroidery. Machineries for Studs, stones and bead work are all in house

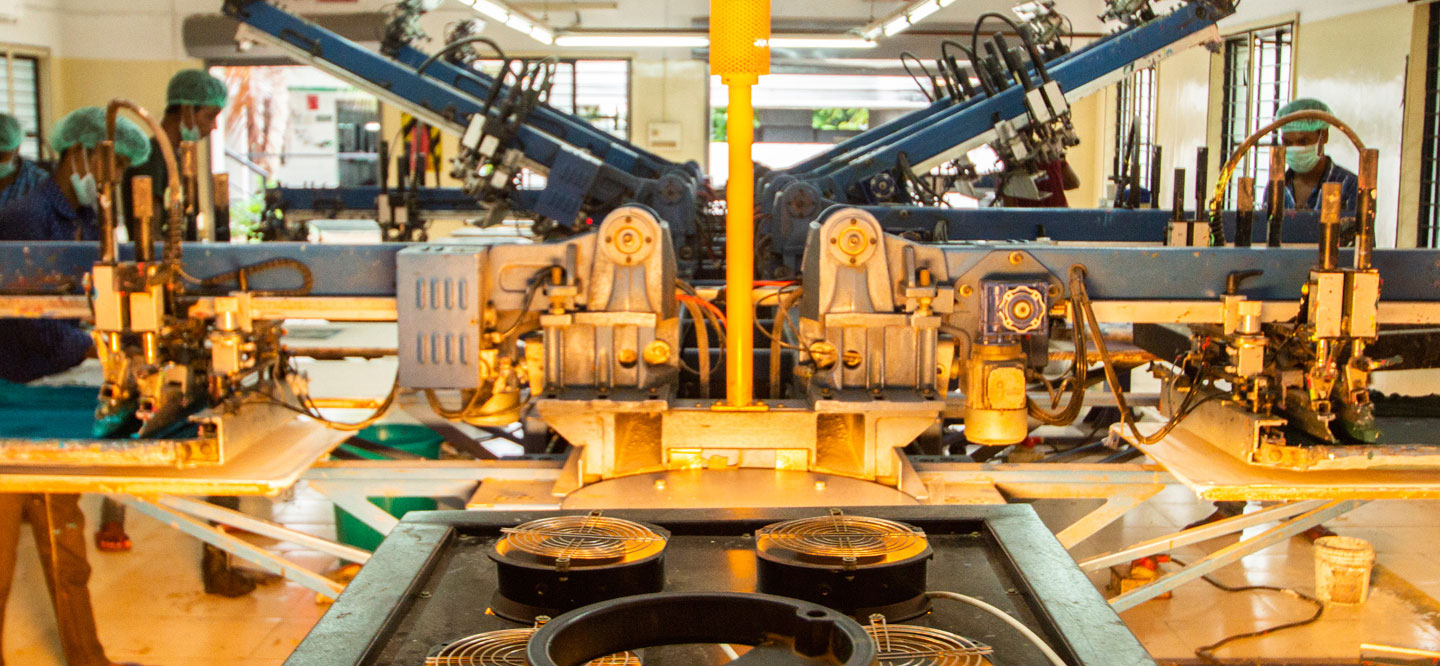

PRINTING

Our printing division is equipped with automated M&R printing machines from the United States. Particularly the Alpha 8 which is M&Rʼs exciting new take on the oval shaped press. It has the capacity to produce 18 different colours simultaneously

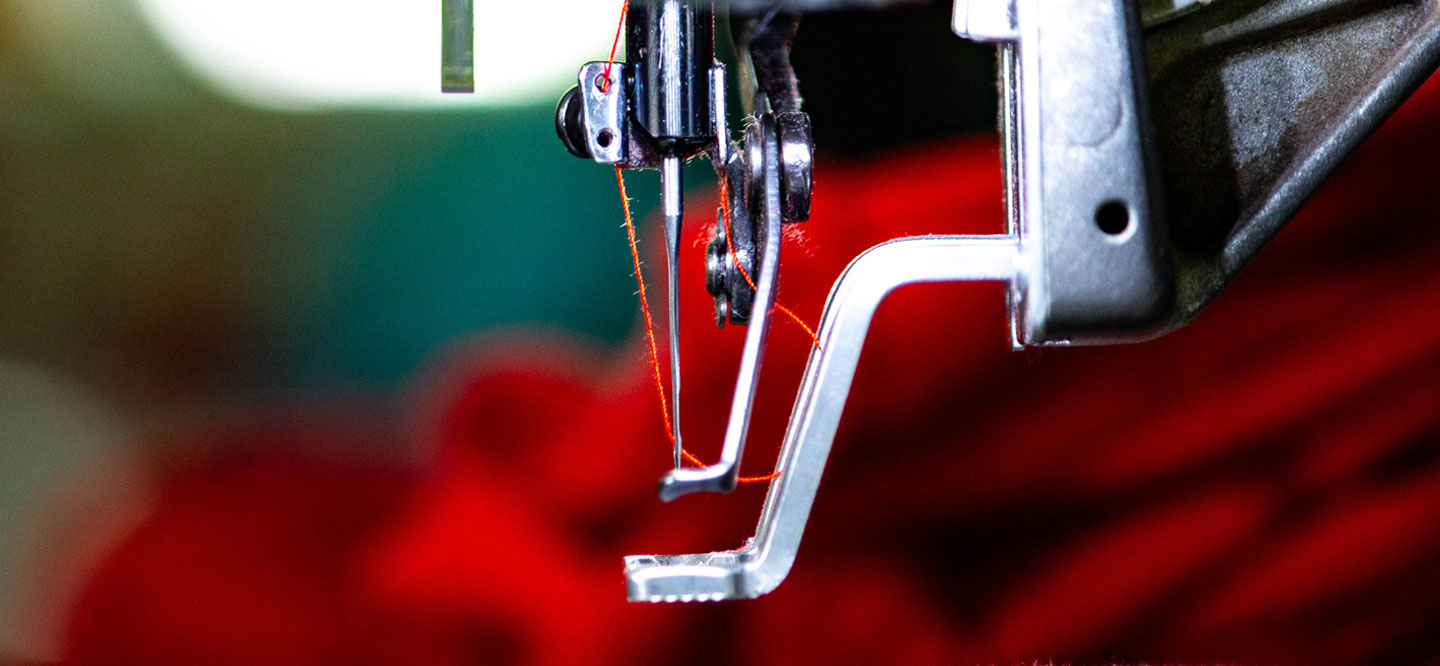

GARMENTING

We have an installed capacity of 20 million garments per year enabled by 3600 machines. Our team is 6000+ strong and growing, producing sustainable knitted garments that cover the entire gamut of the fashion spectrum for men, women, kids & infants.

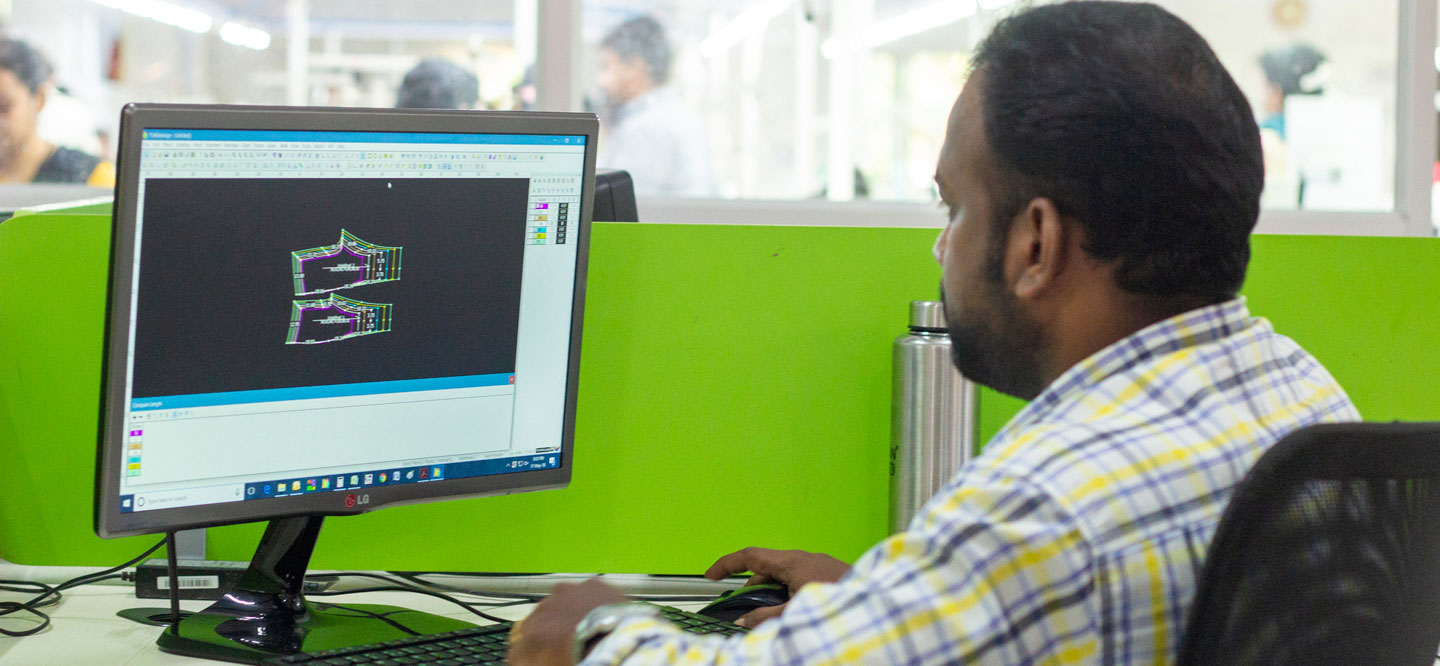

DESIGN STUDIO

“Our Design Studio consisting of a team of 22 members and is equipped withlatest CAD & Trend Software. Our R&D helps generate new fabrics both wi th natural and recycled fibers is equipped with 3D rendering to enable fitting approvals. We create in house collection across all categories for all seasons.”